Accuracy and speed are important in sustaining competitiveness in textile manufacturing. Timing belts are instrumental in these goals, as they ensure that all operations within textile machinery are in harmony. Starting from spinning to weaving to dyeing, these are versatile belts that cannot be easily replaced when it comes to precision, speed, and quality. In high-speed machines for the food industry, employing a good quality Timing Belt is crucial. One such belt can enhance the process and reduce potential downtimes when insignificant service and maintenance are needed. Therefore, by looking at the article, let us understand how these timing belts are changing the norms of textile machinery.

Precision in Motion Control

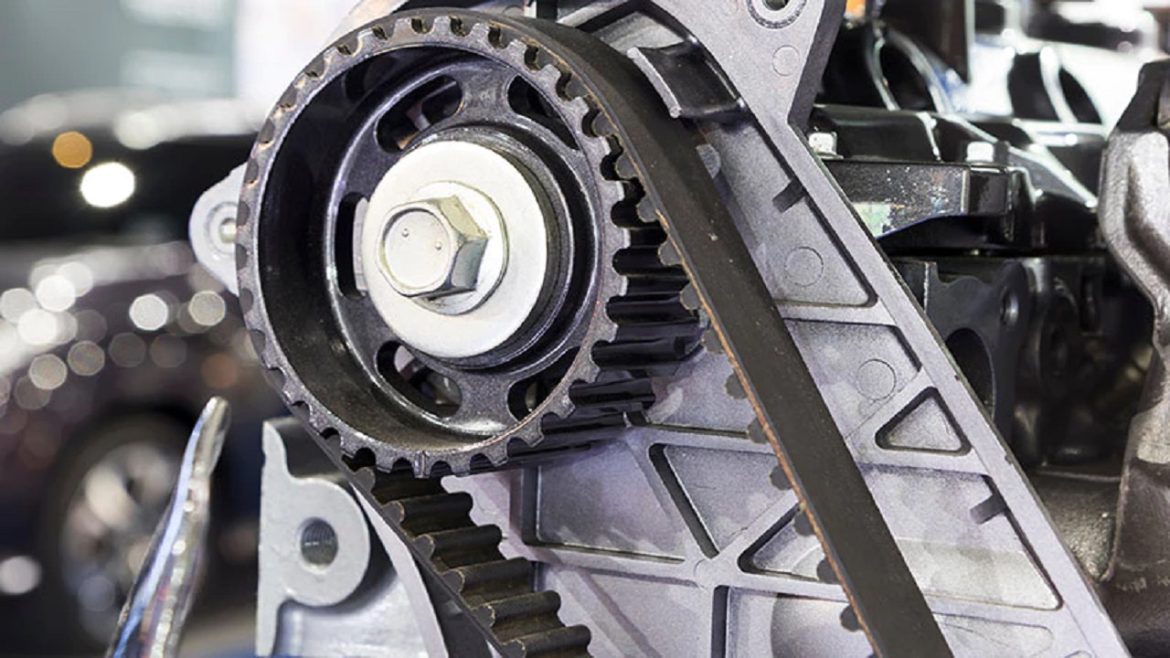

Timing belts are made to ensure proper phasing amongst textile machinery parts without unwanted interference. This accurate motion control is required to achieve a more uniform fabric output and to ensure lower variation with potential for errors. The use of timing belts limits cases of thread misalignment, unequal fabric tension, and other factors compromising quality because all the mechanical parts move in synchronization.

Durability and Longevity

The applications of textile machinery remain more or less constant, putting enormous pressure on the parts used. Timing belts, especially those produced from high-quality polyurethane (PU) or rubber material by reliable brands like ZZR, are designed to handle such steep conditions. Being highly wear and tear resistant coupled with characteristics such as abrasion and chemical resistance, the product offers the longest durability under complicated commercial use.

Enhanced Production Speed

The other major benefit of timing belts for textile machinery is their increased production rate. Its use ensures that the energy is transmitted with high-speed accuracy, and this is because the belts do not slip while transmitting the energy. This capability is most important in the high volume of textiles, where any slowness in speeds or time lost can cause a loss in production.

Provide a Quiet Workplace

It’s often the case that basic mechanical systems in textile machinery can produce a lot of noise, making the working conditions rather hostile. Earlier, belts used to make a lot of noise; newer timing belts work more silently. It improves the workplace ambiance and, without violating industrial noise level standards, makes the environment safer and more productive for the employees.

Low Maintenance Requirements

ZZR brand has launched timing belts that do not require regular maintenance, making the belt suitable for textile machinery. Timing belts are different from chain drives, which usually have the problem of time consumption and high expense due to lubrication and adjustment periods. The low maintenance requirements of timing belts mean the manufacturing process can proceed uninterrupted, increasing production.

Conclusion

Introducing timing belts in the textile machinery is a major business of the firm to improve the speed, quality of the product, and the cost of manufacturing. They remain severe essentials of current textile production due to their high accuracy, durability, and inexhaustible low-connection maintenance. The forgotten element of timing belts means that textile manufacturers could eventually spend slightly more on a higher quality timing belt, ensuring they are ahead in a matter of competition while also being as high in quality as the rest of their production line.