What Safety Precautions Should be Followed When Using Fecon Teeth?

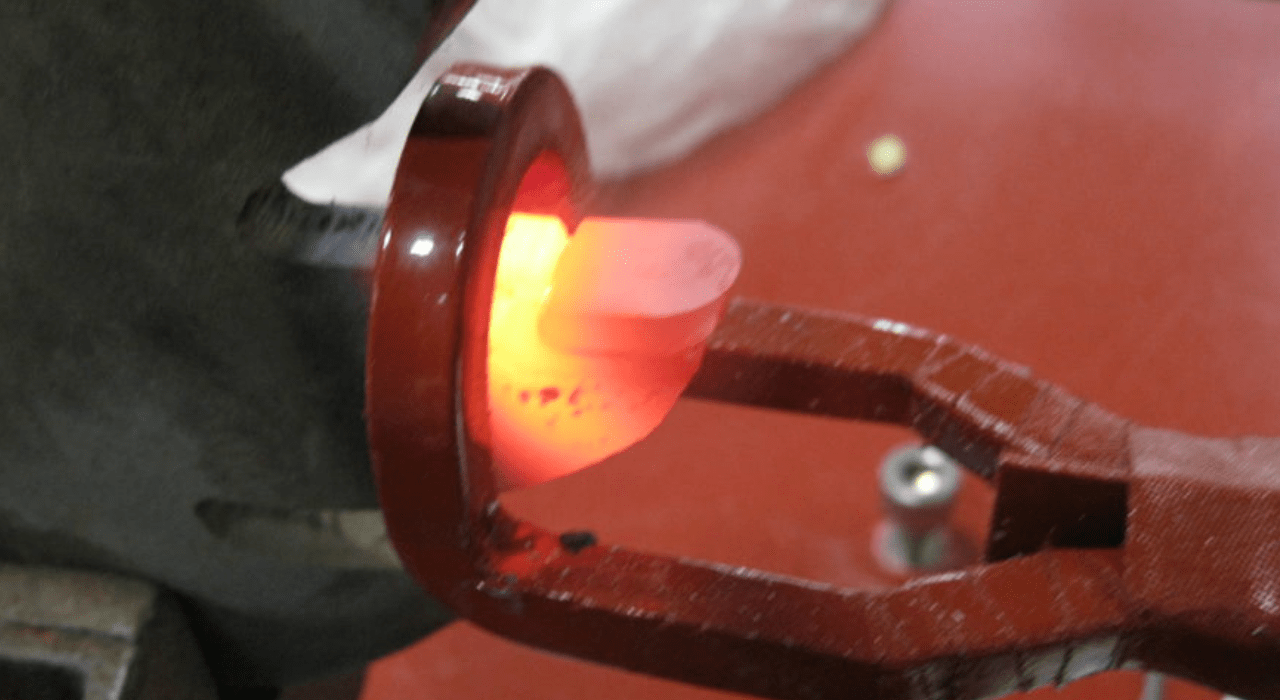

Fecon teeth are designed for forestry mulchers and are crucial for efficient land clearing and vegetation management. They come in numerous styles, inclusive of fixed, replaceable, and bolt-on configurations, depending on the gadget’s requirements and the type of material being processed.

The teeth are usually made from high-energy steel or carbide for durability and lengthy life, and they’re engineered to handle hard, dense substances like timber and brush. Additionally, they function in unique shapes inclusive of heavy-duty or chisel-style teeth to optimize reducing overall performance. Regular preservation and substitute of fecon teeth are essential to ensure consistent overall performance and to prevent harm to the mulcher.

Safety Precautions for Using Fecon Teeth

Whilst the usage of Fecon tooth or any comparable forestry mulcher device, it’s vital to comply with unique protection precautions to save you from accidents and ensure efficient operation

Personal Protective Equipment

Wearing the right non-public protection system is crucial when the usage of Fecon teeth to ensure protection. Essential PPE includes protection glasses to defend your eyes from particles, listening to safety to guard in opposition to loud machinery noise, heavy-responsibility gloves to protect your palms from sharp edges, metal-toe boots for foot safety, and long-sleeve clothing to lessen pores and skin publicity to debris. Adhering to those PPE tips prevents accidents and ensures a more secure working environment.

Machine Inspection and Maintenance

Everyday machine inspection and upkeep are important for secure operation. Look into Fecon teeth for put on, harm, or dullness, and replace them promptly. Test all bolts, fasteners, and moving elements for tightness and proper lubrication, following the manufacturer’s hints. Ordinary protection saves you from system failure and ensures optimum performance. File all inspections and protection activities to track the situation of the system and cope with capacity troubles before they result in accidents or downtime.

Proper Training

Proper Training is vital for effectively running Fecon mulchers. Operators must be thoroughly knowledgeable on machine controls, Fecon teeth preservation, and emergency processes. Proper Training has to cover secure running practices, including dealing with and replacing teeth, in addition to know-how of the machine’s obstacles. Operators need to also be acquainted with manufacturer safety tips. Comprehensive training ensures operators can correctly manage the equipment, recognize potential dangers, and reply as they should in emergencies, improving common protection and performance.

Clearing the Work Area

Before beginning work, thoroughly clear the place of barriers and dangers. Dispose of debris like rocks and branches that could damage the equipment or cause damage. Test for potential dangers which include overhead power traces, risky surfaces, or hidden machines. An easy and danger-loose work region minimizes the threat of accidents and equipment damage, ensuring a safer and greater efficient operation. Often think again about the workings as conditions change to preserve secure running surroundings.

Safe Operating Procedures

Adhere to secure running methods to prevent injuries. Hold a secure distance from the mulcher’s slicing area and keep bystanders away. Operate the machine smoothly and keep away from unexpected or erratic actions. Do not disable or override safety functions designed to protect you and others. Constantly comply with the manufacturer’s operational recommendations and continue to be vigilant, mainly in difficult conditions. Right approaches make certain effective operations and reduce the probability of incidents or machine failure.

Understanding Emergency Stops

Make yourself familiar with the location and operation of emergency forestall controls. Make certain that emergency stops are purposeful and without problems on hand. Practice the usage of these controls to stop the system speedily in an emergency. Knowing how to set off emergency stops successfully prevents accidents and minimizes ability harm in crucial situations. Regularly evaluate and rehearse emergency procedures to make certain spark-off and safe responses if a surprising incident occurs.

Environmental Awareness

Be privy to the surrounding surroundings to ensure safety. Look for overhead risks consisting of energy traces and keep away from working on risky surfaces. Check the vicinity for hidden gadgets or potential dangers that could affect the operation. Environmental consciousness allows the prevention of accidents and application damage, ensuring more secure working surroundings.

Conclusion

Adhering to safety precautions whilst the use of Fecon teeth is crucial for preventing injuries and ensuring effective operation. With the aid of carrying the right PPE, acting normal preservation, receiving thorough training, and following safe working approaches, operators can appreciably reduce dangers. Keeping environmental focus and knowledge of emergency protocols further enhance safety. Prioritizing those measures helps create more secure work surroundings and guarantees that equipment features effectively and reliably.